Promoting the highest industry standards

On-site Inspection Services

Quality of installation

An inspection which focuses on the competency of the installation, for example if there are concerns over the correct sizing of windows or doors, or where the junction between glazing and structure is unsightly.

Manufacturing quality

An inspection which focuses specifically on the quality of the glazing products used, for example if a transom or mullion surface is damaged upon delivery, or where the detail of a joint on framing is questionable.

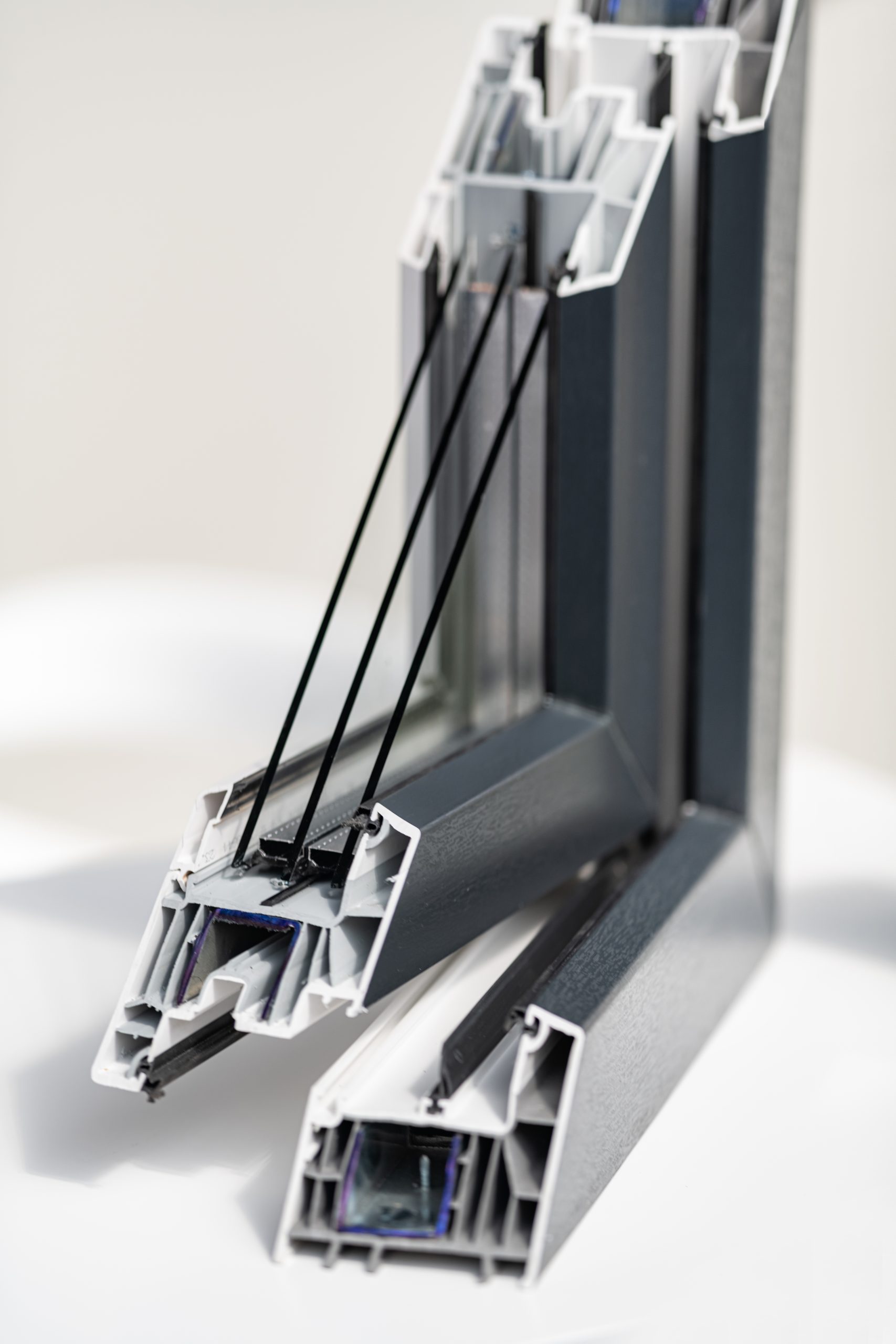

Visual quality – framing

An inspection which focuses on the visual quality of the framing used, for example if a transom or mullion surface is discoloured when the work is completed, or where surfaces of a window frame or infill on a composite door are marked or scratched.

Visual quality – Glass

An inspection which focuses on the visual quality of the glass pane(s) used, for example if a glass surface is marked or blotchy, or where there is distortion when looking through the glass.

Air / Water penetration

An inspection which aims to understand the most likely cause of excess air or water penetration through the glazed element, for example if a water is getting into a building beneath a door, of if a significant draught is felt around a window.

Breakage assessment – Glass

An inspection which aims to understand the most likely cause of the glass pane(s) fracture, for example if a glass pane has unaccountably shattered or developed a crack.

Compliance assessment

An inspection which determines whether the glazing installed is compliant with relevant building regulations and/or relevant standards, for example if installed glazing meets the ventilation requirements of Part F.

Desktop Calculations

Laboratory Testing

For example, after a breakage assessment has confirmed the presence of an inclusion

Static Calculations

For example, to determine barrier loading resistance to glass panes

Condensation Prediction Calculations

For example, to understand the likelihood on condensation at design stage

Heat-Soak Oven Calibration

A regular requirement to ensure correct heat-soak testing of thermally toughened glass panes

Heat-Soak Oven Calibration

A regular requirement to ensure correct heat-soak testing of thermally toughened glass panes

Quality of installation

An inspection which focuses on the competency of the installation, for example if there are concerns over the correct sizing of windows or doors, or where the junction between glazing and structure is unsightly.

Manufacturing quality

An inspection which focuses specifically on the quality of the glazing products used, for example if a transom or mullion surface is damaged upon delivery, or where the detail of a joint on framing is questionable.

Visual quality – framing

An inspection which focuses on the visual quality of the framing used, for example if a transom or mullion surface is discoloured when the work is completed, or where surfaces of a window frame or infill on a composite door are marked or scratched.

Visual quality – Glass

An inspection which focuses on the visual quality of the glass pane(s) used, for example if a glass surface is marked or blotchy, or where there is distortion when looking through the glass.

Air / Water penetration

An inspection which aims to understand the most likely cause of excess air or water penetration through the glazed element, for example if a water is getting into a building beneath a door, of if a significant draught is felt around a window.

Breakage assessment – Glass

An inspection which aims to understand the most likely cause of the glass pane(s) fracture, for example if a glass pane has unaccountably shattered or developed a crack.

Laboratory Testing

For example, after a breakage assessment has confirmed the presence of an inclusion

Static Calculations

For example, to determine barrier loading resistance to glass panes

Condensation Prediction Calculations

For example, to understand the likelihood on condensation at design stage

Heat-Soak Oven Calibration

Heat soak oven calibration is essential for glass processors operating toughening lines. GGF provides expert, independent testing of heat soak ovens to meet the requirements of BS EN 14179.

Option 2 for services

HOW CAN WE HELP?

The GGF consultancy service can be employed to help resolve disputes or disagreements pertaining to a technical aspect of an architectural glass product or glazing installation. Whether its a site inspection regarding the visual quality of a glass pane or framing material, or to confirm whether the installation is compliant, the GGF consultancy service can help bring you peace of mind.

Our Services

On-site Inspection Services

- Quality of installation

An inspection which focuses on the competency of the installation, for example if there are concerns over the correct sizing of windows or doors, or where the junction between glazing and structure is unsightly. - Manufacturing quality

An inspection which focuses specifically on the quality of the glazing products used, for example if a transom or mullion surface is damaged upon delivery, or where the detail of a joint on framing is questionable. - Visual quality – framing

An inspection which focuses on the visual quality of the framing used, for example if a transom or mullion surface is discoloured when the work is completed, or where surfaces of a window frame or infill on a composite door are marked or scratched. - Visual quality – Glass

An inspection which focuses on the visual quality of the glass pane(s) used, for example if a glass surface is marked or blotchy, or where there is distortion when looking through the glass. - Air / Water penetration

An inspection which aims to understand the most likely cause of excess air or water penetration through the glazed element, for example if a water is getting into a building beneath a door, of if a significant draught is felt around a window. - Breakage assessment – Glass

An inspection which aims to understand the most likely cause of the glass pane(s) fracture, for example if a glass pane has unaccountably shattered or developed a crack. - Compliance assessment

An inspection which determines whether the glazing installed is compliant with relevant building regulations and/or relevant standards, for example if installed glazing meets the ventilation requirements of Part F.

Desktop Services

- Laboratory Testing

For example, after a breakage assessment has confirmed the presence of an inclusion - Static Calculations

For example, to determine barrier loading resistance to glass panes - Condensation Prediction Calculations

For example, to understand the likelihood on condensation at design stage - Heat-Soak Oven Calibration

A regular requirement to ensure correct heat-soak testing of thermally toughened glass panes

Emergency Glaziers

Emergency Glaziers GGF Shop

GGF Shop MyGlazing.com

MyGlazing.com Find a GGF Member

Find a GGF Member